Automotive Core Tools

From SPC and MSA to APQP, PPAP and FMEA - Automotive Core Tools provide the framework for your quality management and process optimization in the automotive industry.

In the automotive industry, it is crucial to meet the highest quality standards in order to fulfill customer requirements and the IATF 16949 standard. The effective application of the Automotive Core Tools is the key to ensuring and continuously improving product and process quality.

At Testo Industrial Services, we offer training, comprehensive advice and support in the implementation and optimization of these tools to strengthen your quality systems and increase your competitiveness.

Advanced Product Quality Planning (APQP)

- Planning and implementation: Together, we develop a detailed APQP plan that covers all phases from concept development to series production. Our aim is to ensure the quality of your products through a structured and well-planned development process.

- Process monitoring: We support you in implementing the APQP process and help you to identify and implement suitable measures for continuous improvement.

Failure mode and effects analysis (FMEA)

- Risk assessment and management: Our experts help you to systematically identify and evaluate potential sources of error and their impact on your products or processes. This enables you to develop and implement proactive risk mitigation measures.

- Documentation and updating: We support you in creating and continuously updating your FMEA documents to ensure that all risks are appropriately addressed and documented.

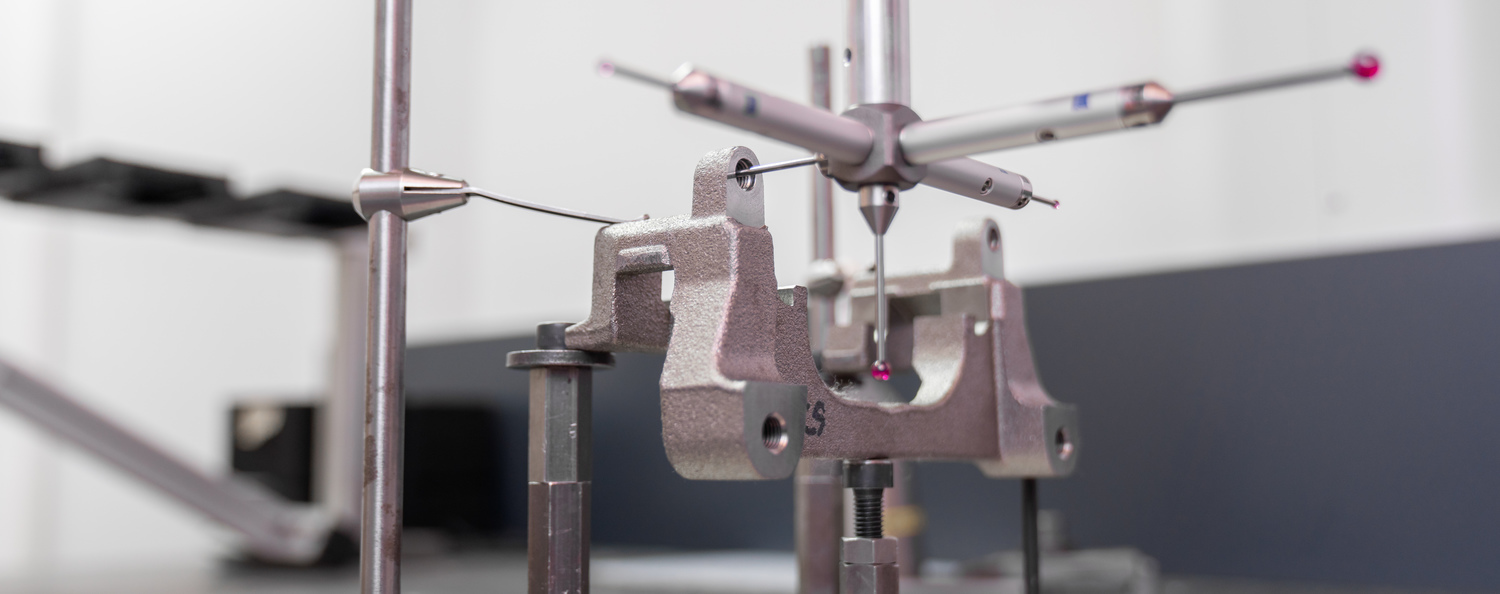

Measurement system analysis (MSA)

- Analysis and improvement: We carry out comprehensive measurement system analyses (MSA according to AIAG and proof of suitability according to VDA5) to qualify your measurement processes for production. Based on the analysis results, we develop measures to improve the measurement processes and their reliability. We help you to avoid pseudo rejects and slippage by setting up safety distances in the production control plan (PLP).

Statistical process control (SPC)

- Implementation and monitoring: We support you in determining the machine and process capability (MFU, PFU) and the introduction of statistical process control based on this. By analyzing process data, we identify deviations and initiate targeted corrective measures.

- Data analysis and troubleshooting: Use advanced statistical tools to analyze your process data. We help you to recognize patterns and identify the causes of process deviations in order to implement targeted improvements.

Production process and product approval (PPAP)

- Documentation: We support you in preparing all the necessary documents and evidence for PPAP approval. This includes the detailed documentation of production processes, carrying out tests and ensuring compliance with all relevant requirements.

- PPAP-test: Take advantage of our support in systematically analyzing the results of the PPAP audit. We help you to identify weak points at an early stage, minimize process risks and ensure sustainable production quality.

Your advantage: Our expertise

- Increase in product quality

- Risk minimization

- Continuous improvement of your production processes

- Increased customer satisfaction & strengthened position in the global market

Learn more about Automotive Core Tools

Are you ready to take your production processes to a new level? Contact us to find out more about how using the Automotive Core Tools can improve your product and process quality. Together we develop solutions to achieve your quality goals and increase your competitiveness.